Why is digital data flow analysis necessary?

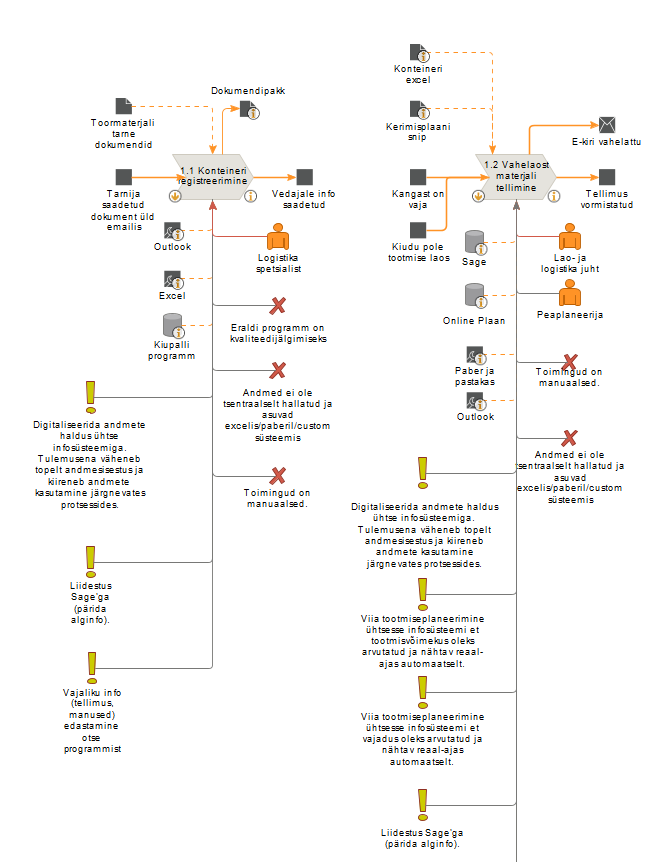

Digital data flow analysis gives you the confidence that digitalisation will deliver real, measurable value and won’t remain at the “trial phase.” During the analysis, we identify where your processes and data are actually located today, uncover bottlenecks and duplications, and define the target state needed to ensure smoother workflows, reduced errors, and automatically generated management information.

Once the current processes and flows have been mapped, we can work with you to model an optimised data flow and develop a clear action plan for system digitalisation. As part of this, we define exactly which integrations, technical solutions, hardware, and software are needed to ensure the solution fits your workflows, is realistically implementable, and supports future business needs and integrations.

Digitalisation Roadmap VS Digital Data Flow Analysis

Digital Data Flow Analysis is not a digitalisation roadmap – it is a highly detailed, supplementary document to the roadmap, and may in fact be more extensive than the roadmap itself.

| Digitalisation Roadmap | Digital Data Flow Analysis |

|---|---|

| Is a general foundational document of the digital strategy, which may include the digital data flow analysis. | Is a detailed foundational document for the tactical activities of digitalisation. |

| Covers the company’s business strategy, management, financial situation, technology, structure, division of work, work culture, and other general business indicators. | Covers specific processes at the data flow level – where the source information comes from, where and how it moves, and through which solutions. |

| Processes are mapped at the business and production flow level. | All processes are mapped at the data flow level. |

| Activities required to initiate or continue digitalisation are mapped. | Specific technologies and hardware needed to achieve the desired outcome are mapped. |

| The result is a business process development plan, also known as a digitalisation roadmap. | The result is a detailed technical specification for the digitalisation of production and warehouse processes, which may serve as a supplementary document to the digitalisation roadmap. |

| Implementation takes place at the business level, meaning tactics for carrying out digitalisation are adopted. | Implementation takes place at the process level, resulting in fully functioning digital solutions. |

Advanced digital technologies

We use modern technological solutions when modelling the desired processes.

Some common problems that a digital and automated data flow helps to solve:

What does the digital data flow analysis process look like?

What does the digital data flow analysis process look like?

Use case

RFID manufacturing solution for Aru Group

Aru Group has implemented a manufacturing monitoring system based on standardised RFID technology. RFID technology enables to digitalise various work processes and stages in both manufacturing and assembly.

Integrating a suitable solution for Aru Group helps them monitor and manage manufacturing activities in real time.

Improved information exchange

Clearer work organisation

Better planning and smoother workflow

Information for operational changes

Overview of the production history

To find out the causes of defects

Data for statistics and reports

Visualisable data

What problem did we solve?

A better overview of the current state and manufacturing processes was necessary. Some information was only available on paper, causing delays when searching for a part’s manufacturing history, for example. There was no quick overview of parts that had not been produced for some reason, causing delays. A significant amount of information noise in manufacturing and assembly led to the simultaneous transmission of information to everyone, sometimes making it difficult to understand who should act on the information and how.

Solution:

The manufacturing solution, digitalised with RFID technology, facilitates production planning and enables operational changes if needed. RFID also allows you to collect important data for compiling statistics and reports, which can be visualised and used to make operational and strategic decisions.

Contact us!

Using modern digital technologies, we create complete solutions for production management, quality monitoring, and tracking of goods and inventory.

Reg.no: 11716262

Vat.no: EE101332363